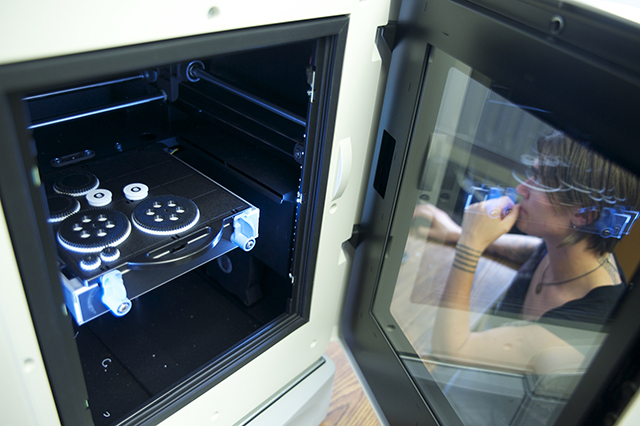

To help bring their creations to life, they used the university’s new 3D printer, a cutting-edge tool that uses computer-generated images to produce three-dimensional objects from rubber, plastic and other malleable materials.

The technology—also known as rapid prototyping or additive manufacturing—has become increasingly popular in recent years at universities and research institutions around the country, says Biology Core manager Anthony Baker.

“It’s an awesome tool that’s allowed us to print everything from water wheels to microscope and printer parts,” says Baker, who purchased the device last November with lottery funds. “With exposure to this technology, our students now have the opportunity to develop skills in 3D design and rendering and be able to generate physical, three dimensional models and functional objects.”

In his State of the Union address earlier this year, President Barack Obama called 3D printing a potential boon to the high-tech job industry. He referred to a public-private partnership in Youngstown, Ohio that is researching the use of 3D printing in large-scale manufacturing. “It’s a technology that’s definitely been getting a lot of attention recently,” Baker says.

Since arriving on campus this semester, HSU’s 3D printer and scanner have been used by a variety of departments, including biology, wildlife, anthropology, geology, psychology, physics and engineering. Projects include graphic design prototypes, machine parts, fossil, bone and rare specimen models, and equipment design.

The first step in creating an object is to design a 3D blueprint using computer aided design (CAD) software like Google SketchUp, SolidWorks or AutoCAD. CAD-equipped computers are located at various locations around campus, including the engineering lab and BioCore.

Once the design has been created an .STL file is sent to the printer. 3D printing uses an additive process, which means that objects are created by adding successive layers of material. HSU’s printer—a Stratasys U-Print SE plus—only uses ABS and degradable PLA plastic.

During the process, the plastic is fed from a spool, heated, then pushed out of the print head at 572 degrees Fahrenheit. Printing can take anywhere between 20 minutes to 20 hours, depending on the complexity of the object and the number of pieces being printed.

Although additive manufacturing has been around since the 1980s, it’s only become more mainstream in recent years, Baker says. 3D printing is popular in higher education because of the numerous opportunities it provides for hands-on learning and research.

“It’s pretty amazing that we have something like this at our school,” says Matt Nyberg, a student in DuRant’s engineering dynamics class, who used the printer to create gears for his motorized robot. “Pretty much anything you can draw, you can create.”

Baker said that in the future, HSU may provide limited printing services to the public at a cost. Possible clients include local artists, business and medical service providers. “The possibilities are endless,” he says.

For more information on HSU’s 3D printer, visit the manufacturer’s web page at www.stratasys.com/3d-printers/idea-series/uprint-se-plus.

The printer is housed in the Biology Core, a campus wide facility that provides workspace for undergraduate and graduate student projects as part of their coursework or for independent and directed research. The facility is located in Science B 230. For more information, call (707) 826-3232.